PALLET RACK CAPACITY

Orlando Office Number

PALLET RACK SAFETY

Rack Capacity

Upright Capacity

The first step to determining the pallet rack capacity of your system starts with the uprights (also called frames). These vertical legs support the weight of the entire pallet rack system. The capacity of an upright depends on a number of factors:

- Steel Gauge

- Post Dimensions

- Beam Spacing

- Welded vs. Bolted

- Depth of Upright

- Height of Upright

- Manufacturer

Your upright capacity must meet or exceed the maximum amount of live and dead load weights on your system within a bay (between two uprights). The capacity of an upright is typically provided in a table from the manufacturer for a specific SKU.

Beam Capacity

The next thing to determine is your beam capacity. Beam capacity is a function of:

- Steel Gauge

- Beam Length/Width/Depth

- Manufacturer

Capacity is listed “per pair of beams” for a uniformly distributed load. This means that the stated capacity is only valid when the load is evenly distributed. For example, for a 96″ beam level with 5,000 lbs/pair capacity you couldn’t put a single 5000 lb pallet right in the center – you would need to spread the load out into two 2,500 lb pallets.

It’s also important to note that your horizontal cross members (beams) are designed to deflect. Beam deflection is a normal occurrence – engineers designate a safe deflection of 0.55% on most beams. Interestingly enough, in some robotics environments like automated storage and retrieval systems (AS/RS) the deflection limit is 0.42%. This means that a fully loaded beam will exhibit some visible deflection – that’s okay!

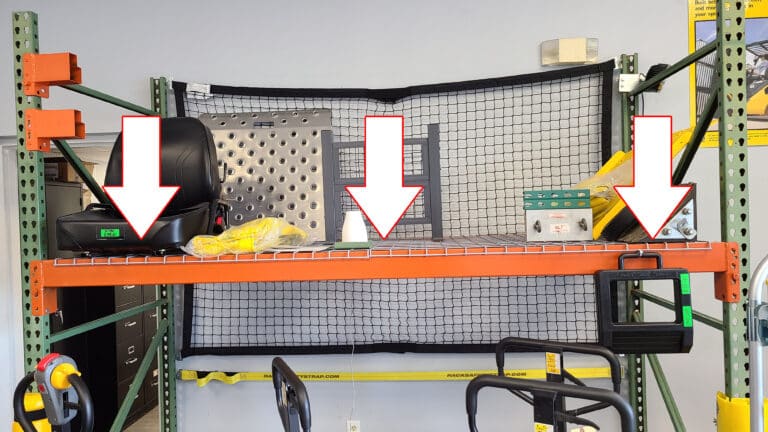

Deck Capacity

Wire decks are placed on the beams of a racking system to provide a platform to place both palletized and non-palletized products. While not every racking application will require the use of wire decks, they are generally recommended as they improve safety, allow for odd-sized loads and are compliant with most fire codes. (Unlike plywood or other solid decking systems.) In the case where wire decking isn’t used, some customer choose to put pallets directly on the beams or use pallet supports.

Wire deck capacity is almost always listed for a “uniformly distributed load”, with standard capacities being in the 2,000 lb – 2,500 lb range. However, heavier capacities are available for custom order when required. While wire decks can help distribute loads evenly, customers must be very careful not to “point-load” the wire mesh of the decking. A 2,500 lb point load could damage or puncture the deck.

As always, if you have concerns over the capacity or integrity of your decking system you should contact a material handling expert.

We have years of experience with pallet rack and have seen it all. Never take safety for granted – give us a call today to see how we can make your rack full-proof.

Beam connection with teardrop style upright

Gravitational forces acting on beam

Waterfall wIre decking in inventory

Find out more about Pallet Rack Capacity

Contact us for more information – we can help with any of your material handling projects. We offer a wide variety of pallet racks for your warehouse. Please fill out the form to the right or reach out using the e-mail or phone below.

Address

9856 South Orange Avenue

Orlando, Florida

32824

sales@mfmh.net

Call Us

407-859-8750