NOVEMBER 2025

Maintenance Made Easy: How CLARK Forklifts Help You Maximize Uptime

When it comes to keeping your operations running smoothly, uptime is everything.

Every minute a forklift is out of service can mean costly delays and decreased productivity. That’s why choosing lift equipment that is built for easy maintenance is a smart move.

It’s also one of the many reasons CLARK forklifts stand out from the competition.

Maintenance Matters

All equipment, no matter how well-built, needs regular preventive maintenance (PM) and occasional repairs due to normal wear and tear.

But not all equipment is equal when it comes to how easy that maintenance is to perform. Choosing forklifts designed with maintenance in mind will save your team time, reduce labor costs, and keep your fleet moving.

Designed for Uptime

CLARK understands how critical uptime is. Their product design teams work directly with their technical service teams to ensure that every new CLARK forklift is not only built to last, but also built to be serviced quickly and efficiently.

The result is faster troubleshooting, easier repairs, and significantly reduced downtime.

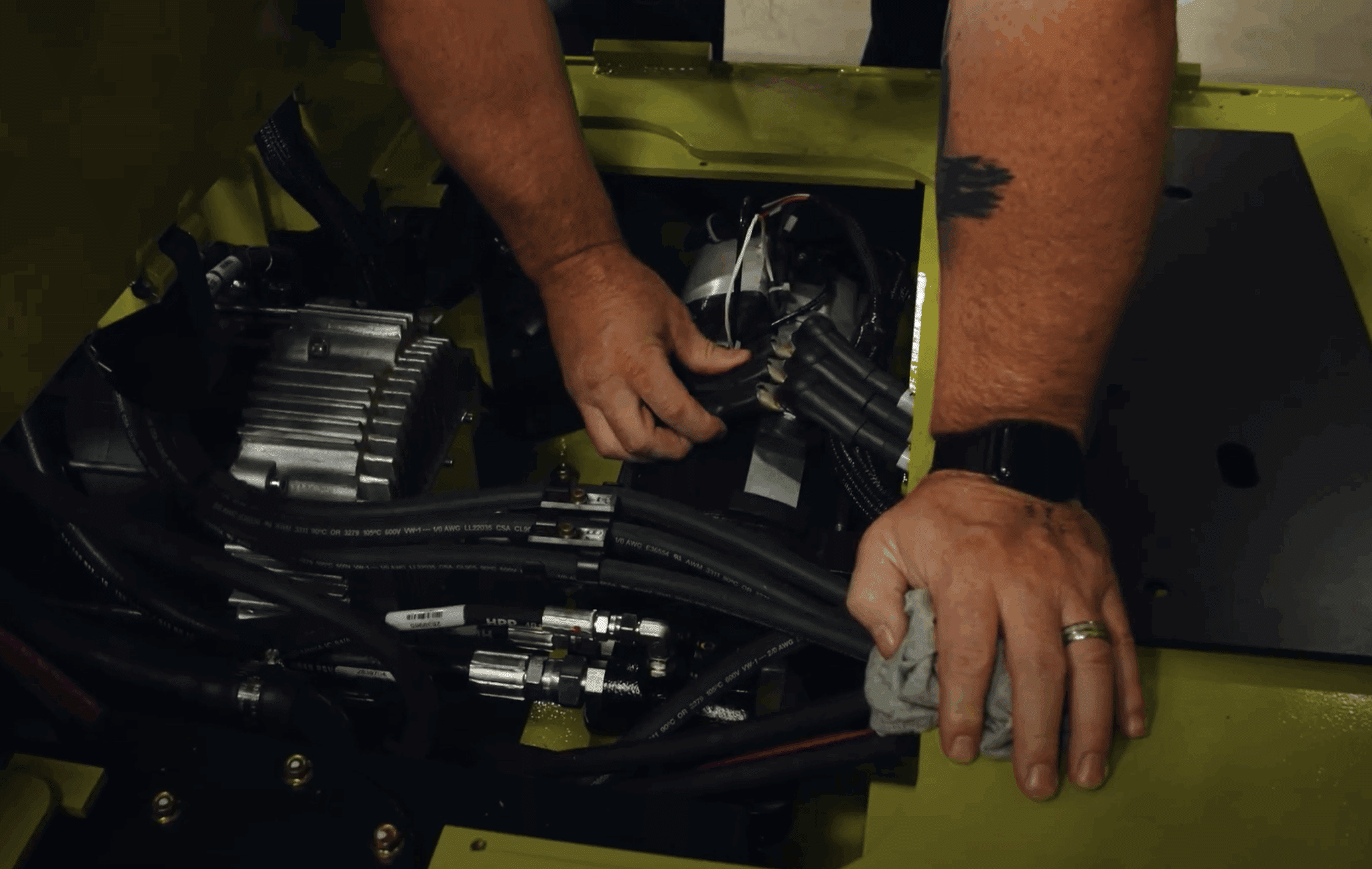

Built for Easy Servicing

CLARK forklifts include thoughtful features that make life easier for technicians. This helps ensure that service doesn’t turn into a time consuming hassle. From accessible engine compartments to repair friendly components, every detail is considered.

Force-Cooled Wet Disc Brakes

Unlike many manufacturers who use drum brakes, CLARK equips its forklifts with force-cooled wet disc brakes. These brakes are more durable, resist overheating, and are much easier to repair if needed. This contributes to lower maintenance costs and longer intervals between service.

Negative Drop Rails

Need to replace rollers or other mast components? With many forklifts, that means disassembling the entire mast, which is time-consuming and expensive. CLARK’s innovative negative drop rails give technicians direct access to rollers and other critical parts. This allows them to complete adjustments or replacements in hours instead of days.

Built-in Access Panels

Service access is made simple with built-in panels that provide quick entry to key components like motors, controllers, and harnesses. When technicians can access everything they need without removing major parts, diagnostics and repairs happen faster. That keeps your trucks in service where they belong.

Standard Tool Friendly Repairs & Servicing

CLARK also makes sure most service tasks can be completed using common tools. This reduces delays waiting on specialty equipment and allows for faster turnarounds during both routine maintenance and unexpected repairs.

Easy Maintenance Means Lower Downtime

When equipment is easy to maintain, preventive maintenance (PM) becomes faster and more effective. Emergency repairs can also be completed without major disruption. For companies that rely on their lift trucks every day, CLARK’s design philosophy provides a real operational advantage.

Discover the CLARK Difference

As an authorized CLARK dealer offering professional forklift maintenance & repair services, we’re proud to offer forklifts that are built for uptime, reliability, and ease of service. Ready to reduce downtime and simplify maintenance?

Browse our full line of CLARK lift equipment or contact us to learn more about how CLARK forklifts can keep your operation moving.