PALLET RACK SALES & INSTALLATION

OFFICE NUMBER

We now offer pallet racks in Brandon, FL

Choose from full range of new and used pallet rack from top brands.

Whether you need selective pallet racks, cantilever racking, push-back rack or any other type of pallet rack, we can help.

With decades of experience serving Florida businesses and a fully stocked warehouse situated in Tampa, we’re able to offer fast and reliable service to our customers in Brandon and all surrounding areas.

Contact us today to get a free quote or more info. Our team of experts would be glad to assist you in selecting the perfect pallet rack system.

Learn More:

Types of Pallet Rack We Offer in Brandon:

-

Selective Rack

-

Push Back Rack

-

Pallet Flow Rack

-

Drive-in/Drive-Thru Rack

-

Cantilever Rack

-

Used & Pre-Owned Rack

-

Pallet Rack Safety Products

Pallet Rack Product Guide

We have a large inventory of top quality rack types:

Selective Rack

A prevalent pallet rack variety, this option offers direct accessibility to every pallet, accommodating both first-in, first-out (FIFO) and last-in, first-out (LIFO) inventory control. A cost-effective choice suitable for diverse operational needs.

Drive-in/Thru Rack

Optimize your total storage capacity. Drive-in rack systems provide access from one side, making them well-suited for LIFO inventory management, while drive-thru systems allow access from both sides, making them an excellent fit for FIFO operations.

Cantilever Rack

Cantilever racks serve as the preferred choice for storing lengthy, bulky, or irregularly shaped items that defy conventional pallet rack storage. They excel in accommodating materials such as lumber, pipes, beams, tubes, and similar items.

Pallet Flow Rack

Rollers enable convenient rear loading and front unloading, making them a superb option for FIFO operations characterized by low SKU counts and high volume

Used Pallet Rack

Pre-owned pallet rack offers significant cost savings and convenience without compromising on storage efficiency and reliability. We have quality racking in stock & ready to ship.

Push Back Rack

High selectivity with increased storage density. Pushback rack is perfect for optimizing your warehouse for maximum storage. We offer both used and new pushback racking solutions.

Use Cases for Pallet Racking

-

General Manufacturing

-

E-Commerce

-

Furniture Manufacturing & Retailers

-

Healthcare

-

Home Improvement Centers

-

3PL (Third Party Logistics)

-

Retail Stores

-

Warehousing

-

Shipping & Distribution Centers

-

Food & Beverage

Create a safer workplace

Keep your team, equipment and inventory safe with our affordable safety solutions:

-

End of Row Guards

-

Guard Rail Systems

-

Steel Bollards

-

Pallet Backstops

-

Post Protectors

-

Rack Safety Netting

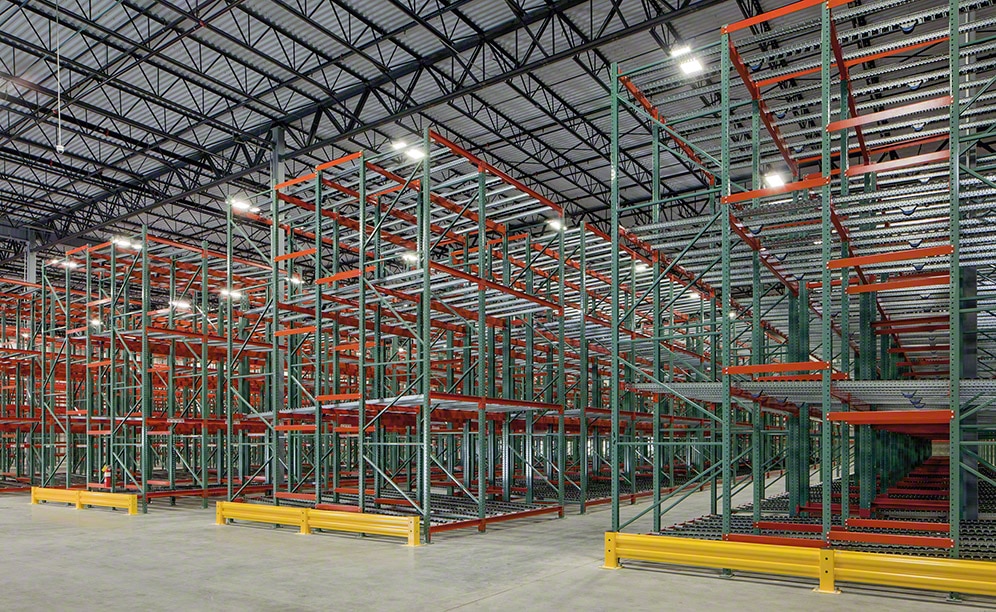

Our Recent Projects

Frequently Asked Questions (FAQs)

Here’s a brief overview of the most popular pallet rack types to help you decide what best fits your needs:

Selective pallet racks offer direct access to each pallet, making them ideal for warehouses with a variety of SKUs and a need for frequent, individualized access to pallets.

Drive-In racks are ideal for high-density storage with a low number of SKUs. They allow forklifts to drive directly into the rack, maximizing storage space but limiting access to specific pallets.

Pallet Flow Racks use gravity to move pallets, making them suitable for FIFO inventory management. This type is beneficial for warehouses with high turnover rates and perishable goods.

Push-Back Racking allows for high-density storage while maintaining selectivity. It’s suitable for warehouses with multiple SKUs and a need for both storage density and accessibility.

Cantilever Racking is designed for the storage of long or awkwardly shaped items, such as lumber, pipes, or furniture, offering easy accessibility.

Narrow Aisle Racking is suitable for maximizing vertical space with narrow aisles. Consider the type of forklift used, as special narrow-aisle forklifts, order pickers or pallet stackers are typically required.

Pallet rack systems are made up of four main components:

Uprights are vertical supports that form the primary framework of the system.

Beams connect directly to the uprights and act as the load bearing horizontal component of the system.

Decking is placed over or into the beams to create a stable surface on which inventory can be placed.

Safety equipment is crucial for preventing injuries, accidents and damage to products or the rack itself.

For more information, read our in-depth guide to pallet rack components or download our handy quick start guide.

Yes, we’ve partnered with APPROVE to make the process of financing your purchase quick & easy. To get started, please visit our financing page or contact our customer service team at 813-374-1133 for assistance.

Pallet racking is preferred over floor stacking due to its ability to maximize vertical space, enhance organization, improve inventory visibility, and facilitate efficient material handling.

Overall, pallet racking offers a more efficient and streamlined solution for warehouse storage compared to floor stacking.

Yes, we offer professional pallet rack installation services in Brandon and throughout Florida’s Suncoast. Contact us today for more information.

Yes, pallet racking systems are highly versatile and can be customized to suit various warehouse layouts, sizes, and storage requirements. This adaptability makes them a practical choice for a wide range of industries.

Yes, it’s very important to consider factors such as load capacity, rack stability, seismic requirements, your operating environment, and adherence to local building codes. Our team is well versed in all aspects of rack safety, and as a customer we’ll guide you throughout the process.

Yes, some pallet racking systems are designed to withstand cold storage conditions.

Our team has extensive experience in cold storage environments and would be happy help you find the right pallet racking for your cold storage facility. Simply give us a call at 813-374-1133 for assistance.

Yes, we offer a full range of new and used pallet rack uprights, beams, decking and safety products that can be purchased individually.

Pallet rack decking refers to the material or structure placed on the horizontal beams of pallet racks to support and secure stored goods. Its benefits include enhancing safety by preventing items from falling through, improving inventory visibility, and facilitating the storage of non-palletized items.

Some common decking types include wire mesh, metal pallet supports, bar grating, punch decking, and perforated decking.

Weight capacity varies widely depending on the type and design of the pallet rack system and its individual components. Factors such as upright post size and beam face height play a significant role in determining what your system’s weight capacity.

Always adhere to the manufacturer’s load capacity guidelines and consult with a structural engineer if needed.

Pallet racking systems are engineered for stability and safety. By preventing the need for floor stacking, they reduce the risk of goods toppling over and create a safer workplace for warehouse personnel.

Regular inspections are crucial for ensuring the safety and stability of pallet racking. Conduct routine inspections and address any damage promptly to prevent accidents.

Yes, for safety purposes pallet racking should be anchored to the floor. Anchoring provides stability and helps reduce the risk of preventable accidents.

We're Committed to Providing Industry Leading Service

EXCELLENT

Pallet Rack Service Area

We provide a full range of services in the Brandon area, including sales, planning & installation.